-

QUALITY

-

PRODUCTIVE INNOVATION

-

DIMENSION

-

PRECISION

Research to optimal product [ + ]

InnovCom [ + ]

Research & Development+Innovation [ + ]

Productive Innovation [ + ]

DIM-i-HOTcooling [ + ]

Productive Innovation 2016 [ + ]

Internationalization [ + ]

Project 1 – Special TOOLS & Manufacturing Systems

FARMI promotes and coordinates research practices, conducts technological monitoring and proposes new solutions and products, creating thus added value compared to what is available in the market. These solutions are not easily tested and do not consist of a simple trial-and-error method, but of a process that is developed and adapted to reality of the business, allowing cost reductions and time savings. All tests, processes and procedures are accordingly described and recorded to optimize future developments.

INNOVATIVE FEATURES:

Development of a hybrid system that allows simultaneous machining and material deposition with great flexibility.

Total investment:

Total amount :€ 187 870.50 EUR

Eligible value:€ 154 415.00 EUR

Non-refundable incentive:€ 77 207.50 EUR

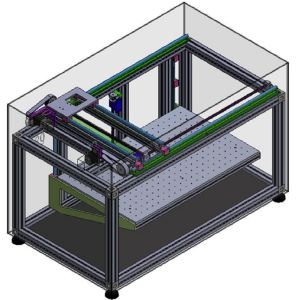

3D CAD drawing of hybrid equipment

Hybrid equipment

LEARN MORE [ + ]

Project 2 - RAPID TOOLS

FARMI promotes and coordinates research practices, conducts technological monitoring and proposes new solutions and products, creating thus added value compared to what is available in the market. These solutions are not easily tested and do not consist of a simple trial-and-error method, but of a process that is developed and adapted to reality of the business, allowing cost reductions and time savings. All tests, processes and procedures are accordingly described and recorded to optimize future developments.

INNOVATIVE FEATURES:

Analyse the use of graphite-filled epoxy resin molds employed in thermoforming, infusion, reaction injection molding (RIM) and resin transfer molding (RTM) processes. These processes usually use low pressures and low processing temperatures, which allows the mold production with low structural strength and therefore lower costs. ;

TOTAL INVESTMENT:

Total amount: € 187.867,50 EUR

Eligible value: € 154.415,00 EUR

Non-refundable incentive: € 77.207,50 EUR

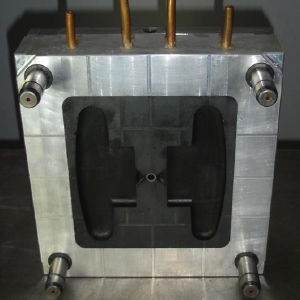

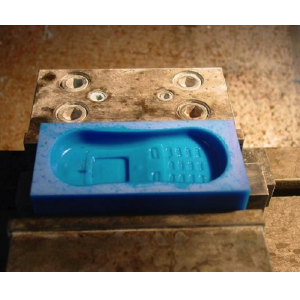

Cavity filled with a resin + graphite mixture

Hybrid mould cavity

Product obtained by RIM (Reaction Injection Molding)

LEARN MORE [ + ]

Project 3 - Milling RP

FARMI promotes and coordinates research practices, conducts technological monitoring and proposes new solutions and products, creating thus added value compared to what is available in the market. These solutions are not easily tested and do not consist of a simple trial-and-error method, but of a process that is developed and adapted to reality of the business, allowing cost reductions and time savings. All tests, processes and procedures are accordingly described and recorded to optimize future developments.

INNOVATIVE FEATURES:

Adapting company´s machining equipment for machining high-quality plastic prototypes with the aim of acquiring special tools for machining and plastic materials for prototype production.

TOTAL INVESTMENT:

Total amount: € 187.867,50 EUR

Eligible value: € 154.415,00 EUR

Non-refundable incentive: € 77.207,50 EUR

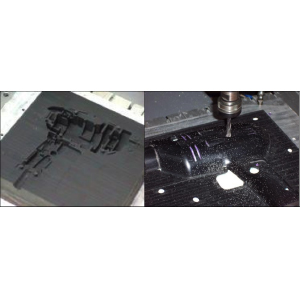

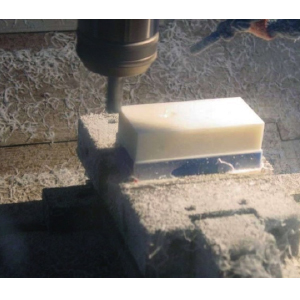

Production of the physical prototype in Teflon (power drill)

Final physical prototype (power drill)

LEARN MORE [ + ]

Project 4 - Micro Manufacturing

FARMI promotes and coordinates research practices, conducts technological monitoring and proposes new solutions and products, creating thus added value compared to what is available in the market. These solutions are not easily tested and do not consist of a simple trial-and-error method, but of a process that is developed and adapted to reality of the business, allowing cost reductions and time savings. All tests, processes and procedures are accordingly described and recorded to optimize future developments.

INNOVATIVE FEATURES:

Development and endogenization of skills in micro-manufacturing and micro-components production from several metal and plastic alloys.

TOTAL INVESTMENT: Total amount: € 187.867,50 EUR

Eligible value: € 154.415,00 EUR

Non-refundable incentive: € 77.207,50 EUR

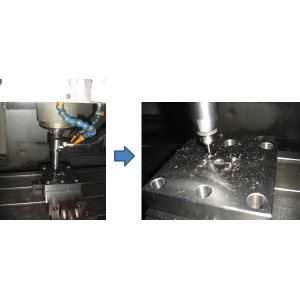

Mould machining stages by micro-milling (headset)

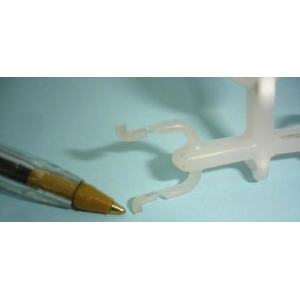

Headset detail – physical object in PP

LEARN MORE [ + ]

Project 5 - Product Development

FARMI promotes and coordinates research practices, conducts technological monitoring and proposes new solutions and products, creating thus added value compared to what is available in the market. These solutions are not easily tested and do not consist of a simple trial-and-error method, but of a process that is developed and adapted to reality of the business, allowing cost reductions and time savings. All tests, processes and procedures are accordingly described and recorded to optimize future developments.

INNOVATIVE FEATURES:

Assessment and implementation of product development strategies more suitable to company’s reality. This project aims to assess the state of art and trends in projects and production of molds, accessories and new products related to the business activities.

TOTAL INVESTMENT:

Total amount: € 187.867,50 EUR

Eligible value: € 154.415,00 EUR

Non-refundable incentive: € 77.207,50 EUR

LEARN MORE [ + ]

Project 6 - Technologie Watch

FARMI promotes and coordinates research practices, conducts technological monitoring and proposes new solutions and products, creating thus added value compared to what is available in the market. These solutions are not easily tested and do not consist of a simple trial-and-error method, but of a process that is developed and adapted to reality of the business, allowing cost reductions and time savings. All tests, processes and procedures are accordingly described and recorded to optimize future developments.

INNOVATIVE FEATURES:

Researching technological opportunities, promoting new R & D partnerships, attending trade fairs and professional events specialized in compilation / description of solutions in terms of identification of associated added value versus state of art of innovative systems in the company.

TOTAL INVESTMENT:

Total amount: € 187.867,50 EUR

Eligible value: € 154.415,00 EUR

Non-refundable incentive: € 77.207,50 EUR

LEARN MORE [ + ]

InnovCom: DirectComposites

Development of a machine for integrating a polymer deposition system, together with a reinforcing fiber adding system and finally a subtractive system (with cutting head for finishing). Manufacture of polymer-based products with deposited reinforcements with automated desired orientation.

INNOVATIVE FEATURES:

New method of additive manufacturing of composite materials; Technology Integration - Molds production with deposition of fibres impregnated with thermoplastic matrix and detail reproduction using high performance thermoplastics.

TOTAL INVESTMENT:

Total amount: € 391 334.32 EUR

Eligible value: € 389 105.22 EUR

Non-refundable incentive: € 258 090.99 EUR

CAD modeling of DirectComposites

Test print with orthogonal deposition of carbon fibres

LEARN MORE [ + ]

Micro Miling 4 Jewellery

Acquisition of know-how and skills in micro-milling

INNOVATIVE FEATURES:

Acquisition of know-how and technical capacities for production support in the jewellery industry, such as incorporating the use of wax machined models with high quality and precision; machining of molds or tools by a milling process for stamping parts; molds machining in alternative materials for the production of castings for alloys and precious materials (silver and gold); creation of models through rapid prototyping for a proper understanding of the desired parameters for the jewellery industry.

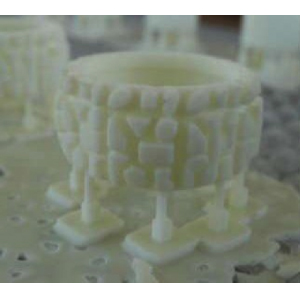

Virtual image of a ring for production by rapid prototyping

PolyJet prototype with support structure

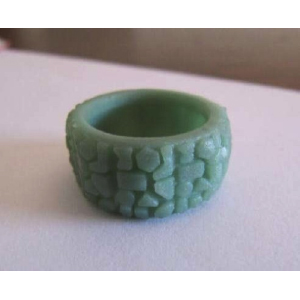

Final wax model

Finished product in silver

LEARN MORE [ + ]

Milling Prototypes

The machining of prototypes of thermoplastic parts is very complex and requires different clamping and positioning technologies. As a result, the machining becomes ineffective and the parts with thin wall thickness lose their strength.

INNOVATIVE FEATURES:

Ability to produce real functional prototypes that "simulate" plastic parts which, when produced, are extremely important for increasing market share.

Inner side of the prototype after machining

Polymer grinding of the holder

Finishing the prototype outer surface

Machined prototype ready for resin removal

LEARN MORE [ + ]

GT Moulds – Thermoforming Molds with Graphites (GT Moulds)

Production of thermoforming molds consisting of a thin surface layer of metal with low melting point. This provides a good surface finish and promotes thermal efficiency. The remaining material of the mold, which consists of a thermosetting resin mix with graphite, is used in machining centers as electrodes.

INNOVATIVE FEATURES:

Development and optimization of a production process for big thermoforming molds at low cost, with sufficient strength properties to support the thermoforming process, as well as a sufficient thermal efficiency to obtain high quality parts.

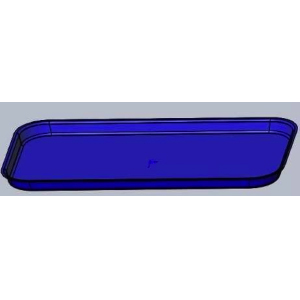

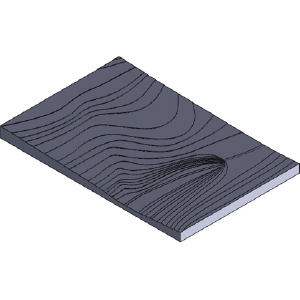

Image of the product modeled in Solidworks

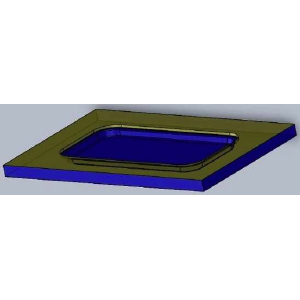

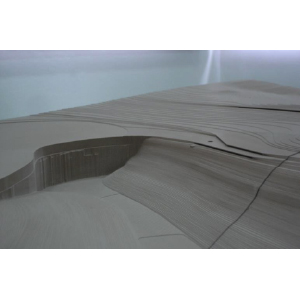

Mould with material thickness

Steel mould for leakage of test models

LEARN MORE [ + ]

Virtual2 Maqueta – From Virtual to Mockup

Software development and introduction of new routine processes that optimize the three-dimensional virtual product design process, planning and assembly of CNC machines. This is geared towards the production of big-scale and low-cost models.

INNOVATIVE FEATURES:

Development of an integrated system focused on virtual handling and production of large scale models.

LEARN MORE [ + ]

Productive Innovation

TOTAL INVESTMENT:

Total amount: € 574.725,05 EUR

Eligible value: € 572.225,00 EUR

Refundable incentive: € 371.946,25 EUR

Achievement award: € 253.586,90 EUR

LEARN MORE [ + ]

DIM - i-HOTcooling (smart Hot-Cooling)

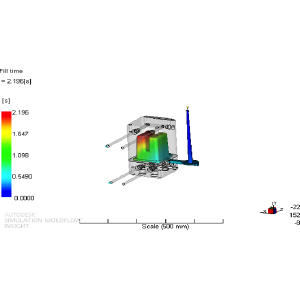

This technique makes it possible to increase the mold temperature close to the melting temperature of the thermoplastic just prior to its injection. Thus, the applied pressure becomes lower, the flow marks are less outlined, the welding lines are in a smaller scale and the admitted flow length is bigger. After fast heating, rapid cooling should occur to reduce the cooling time.

TOTAL INVESTMENT:

Total amount: € 615 089.64 EUR

Eligible value: € 615 089.64 EUR

Non-refundable incentive: € 423 919.69 EUR

Honeycomb-shaped mould cavity

Honeycomb-shaped mould core

Mould filling simulation with PA material

LEARN MORE [ + ]

Productive Innovation 2016

Project name | INOVPROD

Project code | POCI – 02 – 0853 – FEDER – 014471

Main goal | Strengthening competitiveness of small and medium-sized companies

Region of intervention | Central region

Beneficiary entity | FARMI – Reparações, Lda.

Approval date | 07-04-2016

Starting date | 01-01-2016

Completion date | 31-12-2017

Total eligible cost | € 3.288.347,30 EUR

Financial support from the European Union | FEDER – € 2.288.020,00 EUR

FSE – € 13.823,11 EUR

Goals, activities and expected / achieved targets:

1. Increasing significantly the turnover by introducing innovative production methods, by developing new production techniques and using new softwares.

2. Strengthening internationalization by increasing direct sales abroad.

3. Expanding company’s activity fields regarding products and national and foreign markets.

4. Obtaining competitive advantages by increasing not only production efficiency, but also company’s reputation through the introduction of new organizational methods, such as ISO 14001.

5. Expanding the technical content of the proposed solutions to Customers by improving human resources and strengthening individual skills.

6. Strengthening the Service Provision item in overall turnover by improving and increasing provided services.

Co-financed by:

LEARN MORE [ + ]

Internationalization

Project name | FARMI – I18N

Project code | CENTRO – 02 – 0752 – FEDER - 021612

Main goal | Strengthening competitiveness of small and medium-sized companies

Region of intervention | Central region

Beneficiary entity | FARMI – Reparações, Lda.

Approval date | 03-11-2016

Starting date | 01-06-2016

Completion date | 31-05-2018

Total eligible cost | € 142.729,00 EUR

Financial support from the European Union | FEDER – € 59.557,50 EUR

FSE – € 7.265,30 EUR

Goals, activities and expected / achieved targets:

1. Increasing significantly the turnover by introducing innovative production methods, by developing new production techniques and using new softwares.

2. Development of the sales area through a powerful business strategy, especially in the international market, with the aim to acquire new Customers and strengthen business relationships to keep competitors out.

3. Expanding company’s activity fields regarding products and national and foreign markets.

4. Being closer to the international market and gaining greater knowledge of the market conditions.

5. Using and introducing innovative communication and promotional tools to manage and retain Customers, and attract new International Customers.

6. Keeping on with the work already carried out in partnership with the Central Region Knowledge Centers (CDRsp – Center for Rapid and Sustainable Product Development – Polytechnic Institute of Leiria) and development of collaborative knowledge - R&D+i (Research & Development + Innovation).

7. Obtaining competitive advantages by increasing not only production efficiency, but also company’s reputation through the introduction of new organizational methods, such as ISO 14001.

8. Expanding the technical content of the proposed solutions to Customers by improving human resources and strengthening individual skills.

Co-financed by:

LEARN MORE [ + ]